Products

Slitting Machine

ST-102 Slitting Machine

Specialized Slitter thoroughly pursued the slit quality, for composite materials

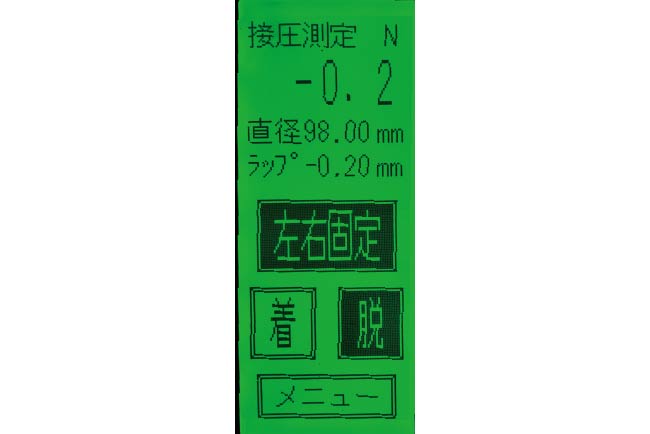

Complete digitization of slitter’s upper and lower knives settings

The contact pressure of the upper and lower knives that control the slit quality, the amount of overlapping between the upper and lower knives, and the toe-in angle (the angle of the upper knife with respect to the lower knife) can be expressed as numerical values. Since the delicate knife alignment of the upper and lower knives can be quantified, it is possible to standardize optimal slitting conditions and obtain steady quality.

|

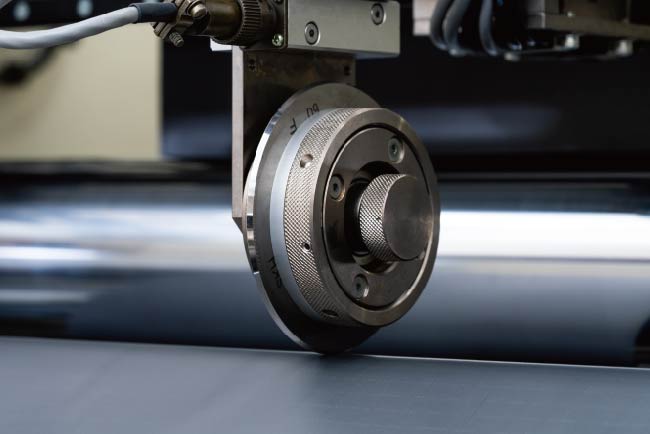

The contact pressure of the upper and lower knives will be detected directly by a built-in contact pressure sensor in the upper knife holder. |

The knife is a cartridge type that can be easily attached and removed, and the knife replacement can be done by one touch operation. |

A unique tension control system enables highly accurate winding control

Adopting the original meandering correction system

Corrects the meandering while following the line speed

A proposal of flexible layout and the slit conditions for each material

We will propose slitting conditions and winding methods suitable for the slit material. According to the customer’s needs, we will improve work efficiency, and provide the superior systems.

Delivering to the manufacturing sites of various composite materials

The slitting machine has been delivered to the manufacturing sites of various composite materials, including Copper Clad Laminate (CCL), Resin Coated Copper foil (RCC), Lithium-ion battery, metal-deposited films, and non-woven fabrics and so on, and received high praise from the market.

Winding side |

|

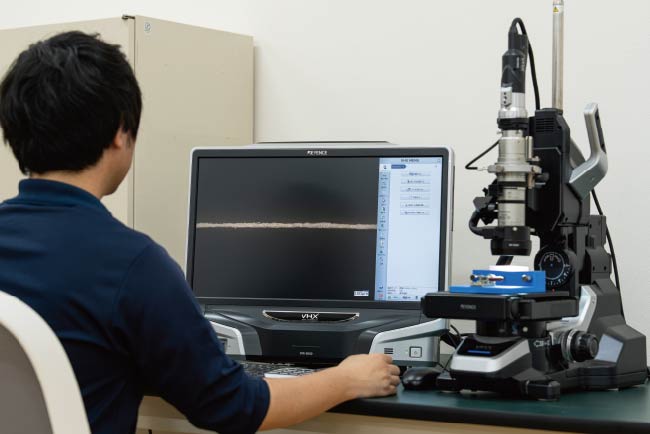

We have a permanent demonstration machine in our companyPlease prepare a sample so that you can experience the difference in the slit due to the delicate adjustment of alignment between the upper and lower knives and the high-precision winding quality. |

|

Inspection of the slitAdjust the knife alignment while checking the slit. |

|

Dedicated options

*This is an optional product for our slitter.

*This is an optional product for our slitter.

Specifications

■Demonstration machine

| Original fabric width/diameter | 250 to 700 mm/Φ400 mm (Max.) |

| Original fabric weight | 50 kg (Max.) |

| Winding diameter | 400 mm (Max.) |

| Unwinding core width | 300 to 800 mm |

| Core diameter | 3 inches |

| Core material | Resin pipe, Paper pipe |

| Minimum slitting width | 80 mm *For new production, up to 50 mm is possible. |

| Running speed | 150 m/min (Max.) |