Products

Paper Manufacturing Slitter

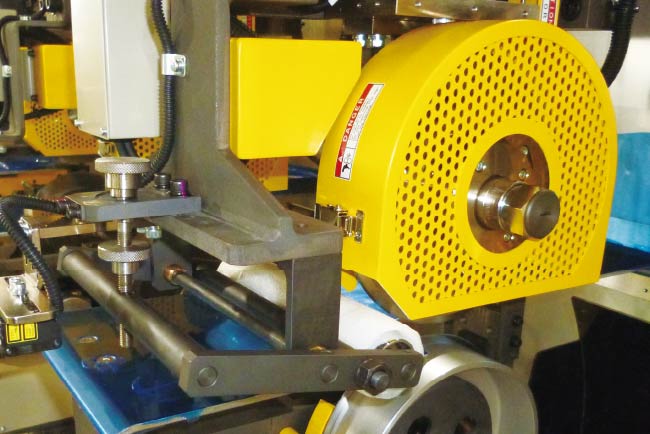

BC-4 NC Slitter

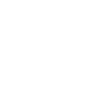

In NC Slitter for cutters, thin knife is used for both the upper and lower knife to minimize generation of paper dust (in case of NC Slitter for winders, the bowl knife is used for the lower knife)

Endless steel belt is usedWhen positioning the slitter unit, it can be easily moved to any position. |

|

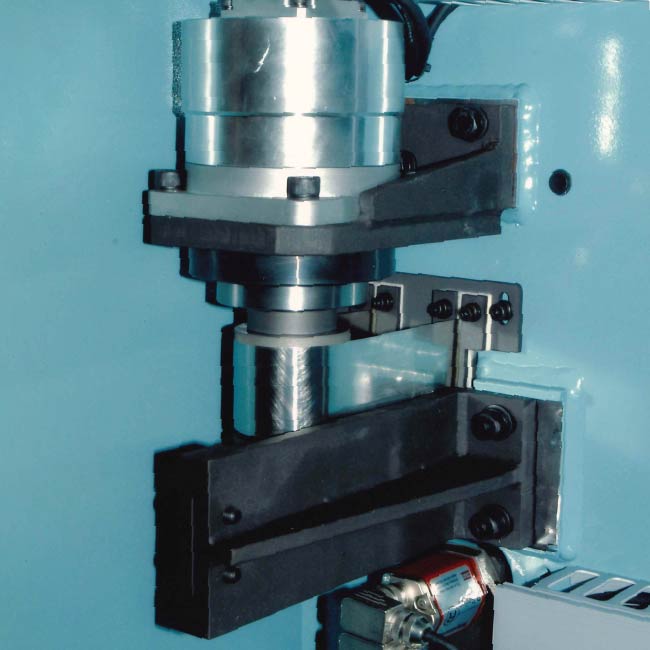

Touch panel is usedOperability has been improved by adoption of touch panel. |

|

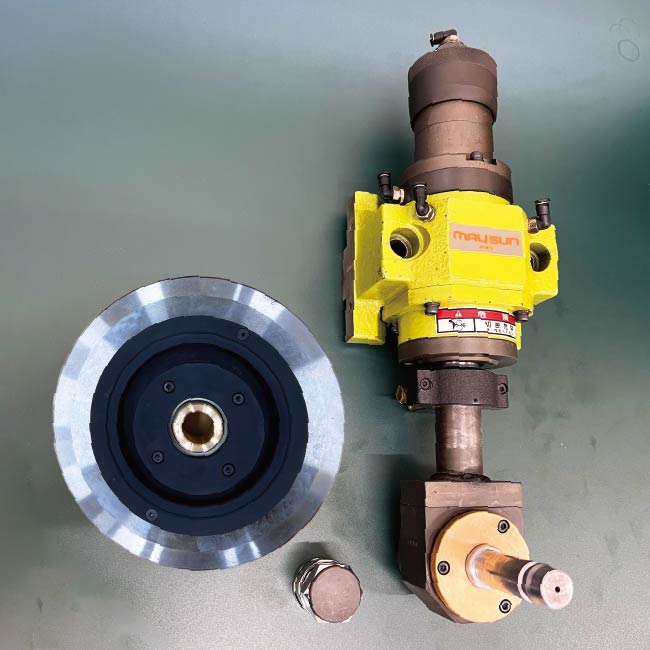

Knife replacement is done by one-touch coupler typeKnife replacement of upper knife is done by conventional one-touch coupler type. |

|

Controlled by geared AC servomotor

Position control is performed by moving to a predetermined position using a geared AC servomotor, and then checking with an absolute position sensor. Corrections will be made as necessary.

Contact pressure control reduces knife deterioration and contributes to product lifespan

Since it is possible to control the contact pressure of each slitter, it not only maintains the sharpness of the slitter knife but also contributes to managing the lifespan of the knife.

Original board allows for long-term maintenance

Since this slitter is using Maysun original board, it is compatible with long-term maintenance.

Moving and fixing are possible with clamp module

A clamp module (clutch) is used for moving and fixing of the slitter.

Amount of knife lapping is adjusted numerically

*When a diameter display (option) is used

For cutters…By using thin knives for the upper and lower knives and controlling the speed, it is possible to suppress the generation of paper dust.

For winders…By using an upper knife holder MSK-IV (lock-type) has enabled usage at high-speed. Line speed: supports 0 to 2,500 m/min

Dedicated options

Specifications

■Demonstration machine

| Slit width (for cutters) | 200 mm or more |

| Slit width (for winders) | 290 mm or more |

| Slit width accuracy | ±0.2 mm |

| Air pressure | 0.5 MPa or more |

Option

| ・Paper holding device (for cutters) ・Diameter display ・Communication with customer’s host computer |

|